When analyzing the efficiency of an electrical transformer, both numerical (quantitative) and categorical (qualitative) features can influence performance. Here’s a structured breakdown:

⚙️ Numerical Features (Quantitative Variables)

These directly affect losses, heat generation, and voltage regulation.

| Feature | Description | Effect on Efficiency |

|---|---|---|

| Input Voltage (V₁) | Primary side voltage in volts | Deviation from rated voltage increases core losses |

| Output Voltage (V₂) | Secondary side voltage in volts | Affects voltage regulation and load efficiency |

| Load Current (I₂) | Secondary current in amperes | Higher current increases copper losses |

| Frequency (f) | Supply frequency in Hz | Core losses depend on frequency; efficiency decreases if frequency deviates from design |

| Rated Power (kVA/MVA) | Transformer capacity | Larger transformers often have higher efficiency due to reduced relative losses |

| Core Loss (Iron Loss, W) | Constant loss from hysteresis and eddy currents | Higher core loss reduces efficiency at no-load |

| Copper Loss (W) | Load-dependent loss due to winding resistance | Major loss component under load; increases with square of load current |

| Temperature Rise (°C) | Rise above ambient | Excessive temperature increases resistance and reduces efficiency |

| Ambient Temperature (°C) | External temperature | High ambient reduces cooling efficiency |

| Winding Resistance (Ω) | Electrical resistance of windings | Higher resistance means higher copper losses |

| Magnetizing Current (A) | Current required to energize the core | Affects no-load losses |

| Power Factor (cos φ) | Load power factor | Poor power factor reduces apparent efficiency under load |

| Oil Level / Flow Rate | In oil-cooled transformers | Affects cooling and indirectly efficiency |

| Flux Density (Tesla) | Magnetic field strength in the core | High flux density increases core losses |

🔧 Categorical Features (Qualitative Variables)

These describe material, design, and operational characteristics.

| Feature | Categories / Examples | Effect on Efficiency |

|---|---|---|

| Transformer Type | Distribution, Power, Auto, Instrument, etc. | Efficiency varies by design and application |

| Cooling Method | ONAN, ONAF, OFAF, OFWF, Dry type | Affects heat dissipation and continuous load capability |

| Core Material | CRGO steel, Amorphous steel, Ferrite | Better materials reduce hysteresis and eddy current losses |

| Winding Material | Copper, Aluminum | Copper offers lower resistance → higher efficiency |

| Insulation Class | Class A, B, F, H | Determines allowable temperature rise and reliability |

| Mounting Type | Pole-mounted, Pad-mounted, Indoor | Affects ventilation and cooling efficiency |

| Load Type | Industrial, Residential, Non-linear, Balanced | Load characteristics influence harmonic losses |

| Connection Type | Δ–Y, Y–Δ, Y–Y, Δ–Δ | Influences harmonics, neutral current, and phase balance |

| Regulation Type | Fixed tap, On-load tap changer (OLTC) | Affects ability to maintain efficiency under varying loads |

| Cooling Medium | Air, Mineral oil, Ester oil | Impacts cooling and thermal performance |

| Operating Environment | Urban, Rural, Coastal, Industrial | Dust, humidity, and salinity can degrade insulation efficiency |

| Manufacturer / Design Standard | IEC, IS, ANSI designs | Standards ensure different levels of efficiency compliance |

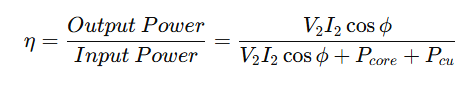

🧮 Efficiency Relationship Example

Where:

- ( P_{core} ) = Iron (core) loss (constant)

- ( P_{cu} ) = Copper loss (variable, ∝ I²)

1. Where Aluminum Windings Are Used

| Transformer Type | Typical Winding Material | Reason / Justification |

|---|---|---|

| Distribution Transformers (≤ 500 kVA) | ✅ Aluminum or Copper | Aluminum is cheaper and lighter — used widely by utilities for pole-mounted and pad-mounted distribution transformers. |

| Power Transformers (> 1 MVA) | ✅ Copper (mostly) | Copper offers higher conductivity and better mechanical strength, essential for high-current, high-voltage operations. |

| Dry-Type Transformers | ✅ Both (depending on cost and space) | Aluminum used where cost and weight are more critical than compactness. |

| Instrument / Control Transformers | ✅ Copper | Accuracy and stability are more important — copper preferred. |

2. Aluminum vs Copper – Comparison for Transformer winding

| Property | Copper | Aluminum |

|---|---|---|

| Conductivity | 100% (reference) | ~61% of copper |

| Density | 8.96 g/cm³ | 2.70 g/cm³ (≈ 3x lighter) |

| Cost | Higher | ~50–60% cheaper |

| Cross-sectional Area | Smaller (for same current) | Needs ~1.6x larger cross-section |

| Oxidation | Minimal | Forms oxide layer (must be handled carefully) |

| Mechanical Strength | Stronger | Softer; more prone to creep under stress |

| Thermal Expansion | Lower | Higher — needs design compensation |

| Efficiency Impact | Higher efficiency, smaller losses | Slightly lower efficiency due to higher resistance |

3. Industry Practice

- Utilities (like in India, USA, Europe) often use aluminum-wound distribution transformers because they’re:

- Cheaper upfront

- Lighter (easier to mount on poles)

- Sufficient for typical load profiles (80–90% rated load)

- Industrial users or private installations prefer copper-wound transformers for:

- Better overload capacity

- Lower operating losses (high

In summary:

✅ Yes — aluminum windings are common in smaller and cost-sensitive distribution transformers.

❌ Copper is dominant in high-capacity or precision transformers where performance and reliability matter more than cost.